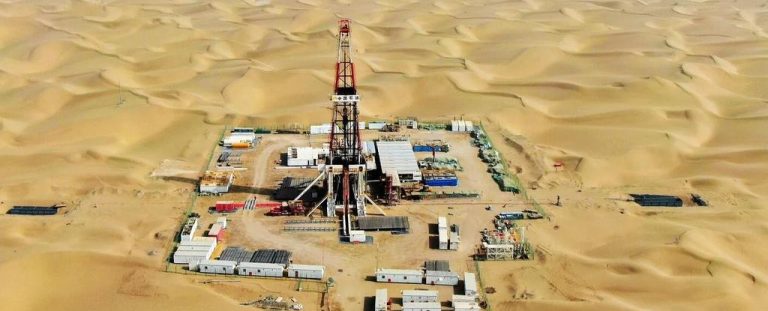

RIGRS Oil Machinery Improving Drilling Performance And Safety

Professional Manufacturing Global Service Coverage

Products Catagories

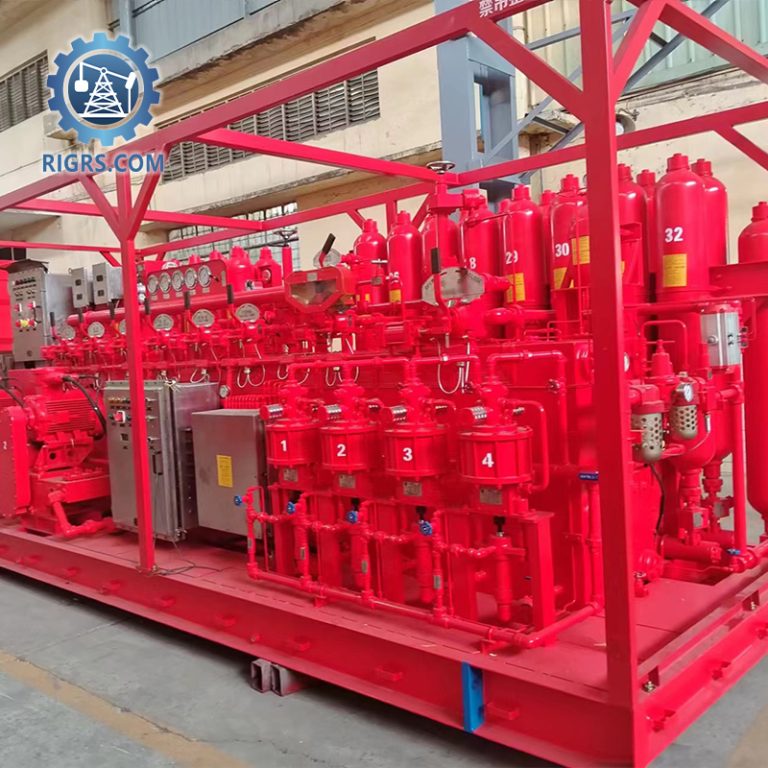

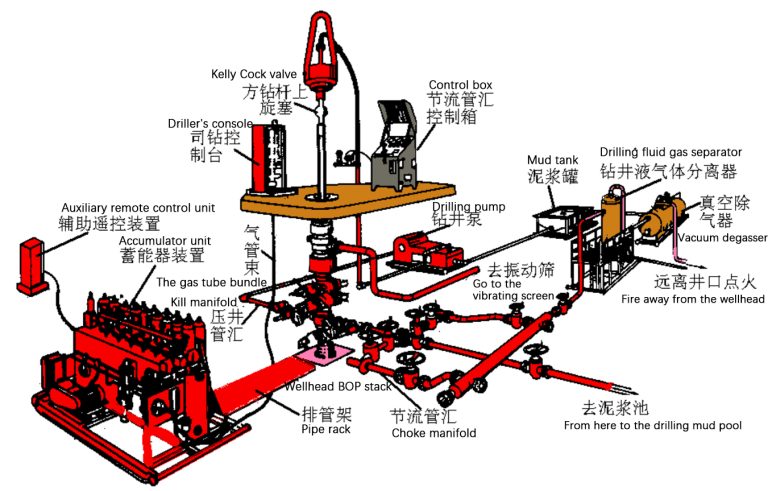

Well control equipment is a combination of equipment used to control wellhead pressure, prevent blowouts, and handle other abnormal conditions related to well pressure. The main components of well control equipment include blowout preventers, choke manifolds, well kill manifolds, etc.

Wellhead equipment is a series of devices installed on the wellhead. Their functions are to control the flow of oil and gas, adjust pressure, prevent leakage, and perform various monitoring and control operations. The main components of wellhead equipment include valves, Christmas trees, etc.

The main purpose of well control equipment is to effectively control the wellhead pressure during drilling and production to prevent dangerous accidents such as blowouts. As a key component, the hydraulic controller is responsible for accurately monitoring and controlling the hydraulic system.

Well control equipment is a strong line of defense against the challenges of high-pressure fluids. Their existence and effective operation ensure the safety of oil and gas production operations. FMC Manifold and Chiksan Swivel Joint are an important part of it.

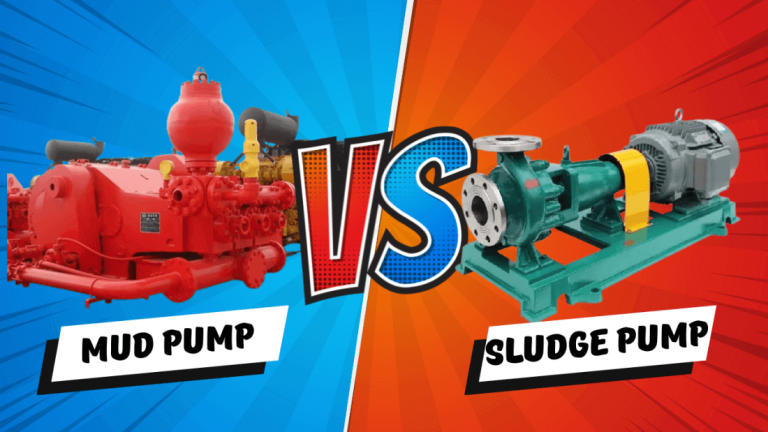

In oil and gas drilling operations, drilling mud pump Package are indispensable and important equipment, including mud pumps, diesel engines and gearboxes, which provide strong power support for the drilling process.

In the field of oil drilling, drilling lifting tools are important equipment to ensure efficient and safe drilling operations. Among them, hydraulic power tongs, as a key tool, play an irreplaceable role. Hydraulic power tongs provide powerful power through the hydraulic system and can easily handle the tightening and disassembly of various pipe fittings.

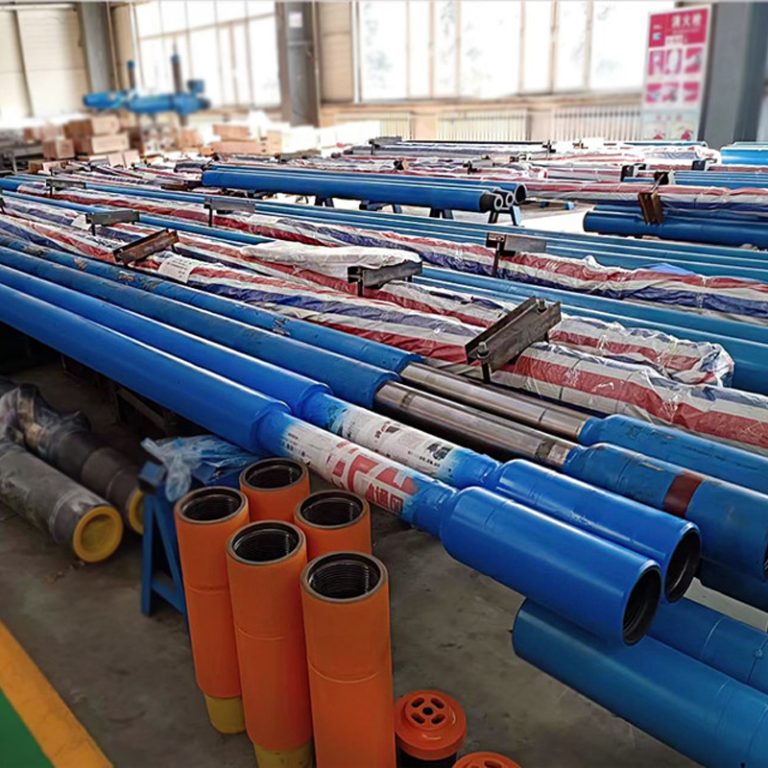

Downhole tools mainly include: Drill Stabilizer, Fishing Tool and Drilling jar.The stabilizer is installed at a specific position on the drill string. Its main function is to reduce the bending and vibration of the drill string.

Drilling operations are usually carried out under extremely harsh environmental conditions. Equipment is subjected to huge pressure, wear and corrosion for a long time, and parts will inevitably wear out and fail. Repair kits are a set of carefully combined parts and repair tools, usually including seals, oil seals, bolts, nuts, gaskets, etc., as well as necessary repair tools.

Let's start your project to be realized

Let’s initiate your petroleum project and turn your vision into reality.

ADVANTAGES

Why Choose RIGRS Oil Machinery

Choose RIGRS for reliable solutions and exceptional service tailored to your specific requirements.

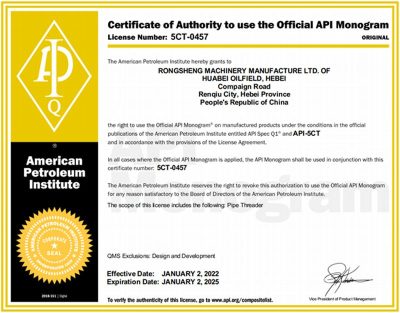

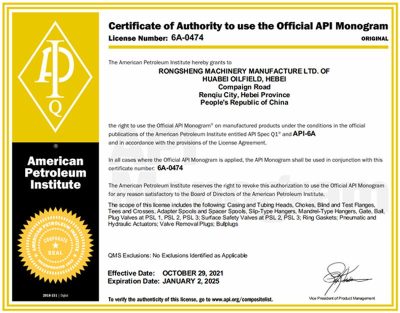

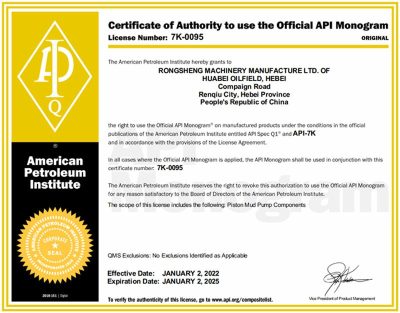

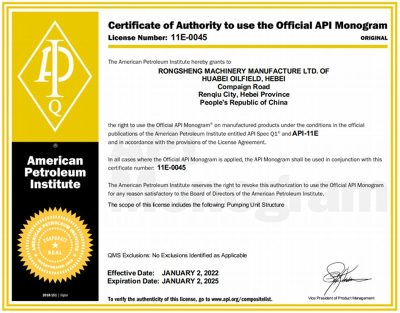

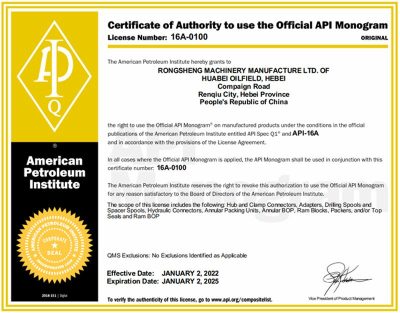

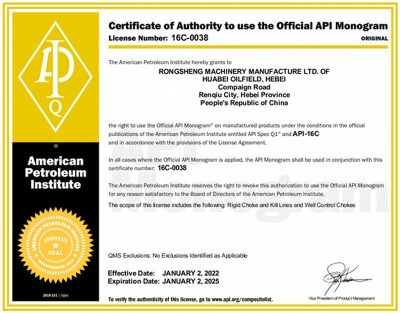

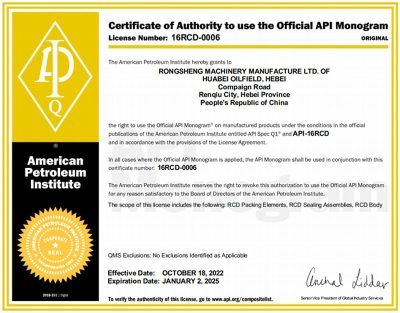

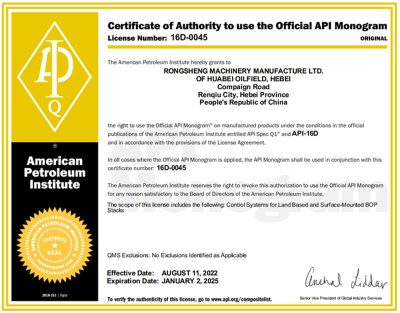

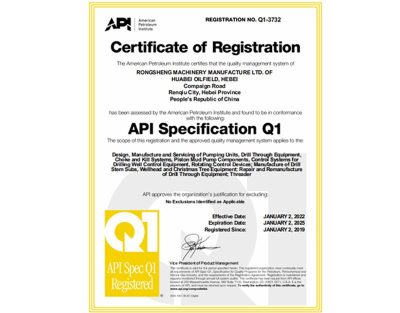

- Holding API certificates since 1998, continuously for over 20 years

- Customization services available according to drawing requirements

- Ready for client and third-party factory inspections at any time

- One-on-one service with technical engineers, providing comprehensive solutions

- Delivery of regular products within 10 days

- One-year warranty for regular products

- Accepting multiple payment methods (T/T, L/C, MoneyGram, Credit Card, PayPal, Western Union,etc.)

- Fluent communication in English, Russian, Spanish, and Arabic

Discover RIGRS: Explore Our Extensive Catalog

Explore RIGRS’ comprehensive catalog to find cutting-edge solutions tailored to your needs.

Experienced Team

RIGRS Oil Machinery's expert team excels in delivering top-quality products and service.

Modern Equipment

RIGRS Oil Machinery utilizes modern equipment for high-quality and reliable performance.

Innovative solutions

RIGRS Oil Machinery delivers excellence with innovative solutions and reliable performance.

About Us

About RIGRS

RIGRS Oil Machinery CO.,Limited was established in 2006. RIGRS is located in China’s petroleum equipment processing base, Renqiu city, Hebei Province, People’s Republic of china. Take advantage of the cluster to develop rapidly. RIGRS has 12 professional and technical personnel, 45 production workers, 13 professional inspection personnel, 50 large-scale professional processing equipment, more than 40 professional testing equipment, plant area of more than 40,000 square meters.

- Quality

RIGRS Oil Machinery provides premium, high-performance petroleum equipment, ensuring unmatched quality and reliability in every product.

- Reliability

RIGRS Oil Machinery delivers dependable petroleum equipment, ensuring consistent performance and reliability for all your operations.

Service

One-stop integrated procurement

Streamline your petroleum equipment procurement with RIGRS Oil Machinery’s all-inclusive service—your one-stop solution!

- Comprehensive Solutions

All petroleum equipment needs fulfilled efficiently and effectively.

- Streamlined Procurement

Simplify sourcing with our integrated service and support.

- Global Supplier Network

Access to top-quality products from trusted global suppliers.

- Expert Guidance

Guidance and advice from industry-leading professionals for tailored solutions.

Trusted by 25,000+ world-class brands and organizations of all sizes

Trusted by countless satisfied customers for our reliability and exceptional service.

Testimonials

What Our Clients Say?

Our Blog

Latest News & article